Automatic Multi-function Vertical Form Fill Seal Packaging Machine

Automatic Multi-function Vertical Form Fill Seal Packaging Machine is a popular design for filling materials in small packaging.

Product Name: Multi-function Vertical Form Fill Seal Packaging Machine

Bag width: 200 - 350mm

Bag length: 50 - 450mm

Packing speed: 30-60 bags/min

Power: 3.0kw/3.5kw/4.0kw

Delivery Time: 35 working days.

Payment Term: T/T, L/C, PayPal, Western Union

Automatic Multi-function Vertical Form Fill Seal Packaging Machine is a popular design for filling materials in small packaging.

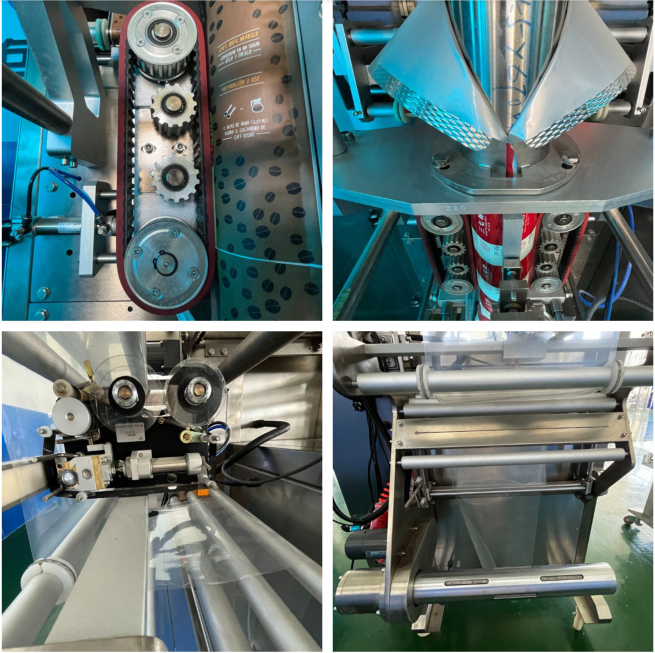

Automatic Multi-function Vertical Form Fill Seal Packaging Machine consists of:

1. Basic packer

2. Ten or fourteen heads combined weigher

3. Z-type material conveyor

4. Supporting platform

5. Finished product conveyor

Working principle of Automatic Multi-function Vertical Form Fill Seal Packaging Machine:

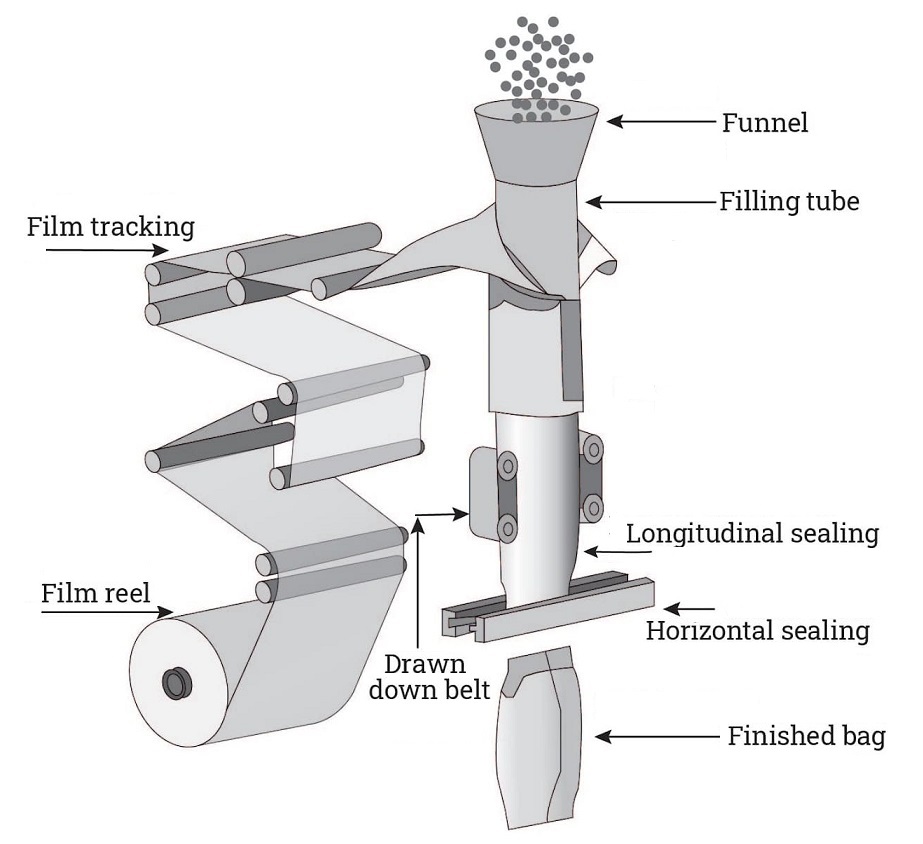

The VFFS is made of the following sections:

1. Dosing system

2. Forming area

3. Film feeding and alignment

4. Sealing and cutting

Step 1: Packaging material unwinding

The packaging material(for example, some aluminum foil, plastic laminate, or even paper) must be rolled out, is delivered in rolls in order to be used. The film is pulled out and tensioned thanks to several rollers and a weighed pivot arm in order to be ready for a good forming. The unwinder is positioned at the back of the machine.

Step 2: Forming the pouch

The material is fed flat and tensioned to the filling tube. The packaging material is twisted around forming the shoulder or collar of the forming tube and pulled all along the tube.

Step 3: Vertical sealing

After the packaging material is well wrapped around the forming tube, then a 1st sealing, on the side, can be done. The forming collar and the width of the packaging reel must be such that there is an overlap when wrapping the material around the tube. A couple of sealing jaws, or sealing bars, is then used to press against each other the 2 parts of the overlapping material and weld them, often thanks to heating, to create a side seal.

Step 4: Bottom sealing

The material is pulled down by a length corresponding to the desired pouch length. Then The product cannot yet be fed to the filling tube as there is no bottom seal to the pouch. It is done by another couple of sealing bars that are also welding the material through pressure and heating.

Step 5: Product filling

The dosing system positioned about the forming tube can finally be run to dose the amount of product to dose. The material falls down through the forming tube and inside the open pouch being manufactured.

Step 6: Top sealing

Once the dosing of the product has been done, then the same sealing jaws that performed the bottom seal are activated again to, this time, create the top seal and close the pouch.

The sealing jaws can also have a vertical movement up and down which allows you to pull the film all along the machine and unroll it from the reel positioned on the unwinder.

Step 7: Cutting and discharge

After closing the pouch, it is then cut and falls down to a collection system, typically a belt conveyor that brings the pouch to the next packaging step (putting it in a box...)

Depending on the technology, a filling speed of 30 to 80 pouches per minute for intermittent VFFS packaging machines.

Application of Automatic Multi-function Vertical Form Fill Seal Packaging Machine:

In the food industry, package snacks, bakery items, fresh produce, etc. a wide range of products.

In the pharmaceutical industry, package pills, tablets, and other medications.

Other industries, pet food, household products, personal care products, etc. also used this machine for packing.

The versatility and flexibility of VFFS machines make them suitable for packaging products of different shapes, sizes, and consistencies. VFFS machines can be adapted to meet the specific needs of each product and industry.

Specifications of Automatic Multi-function Vertical Form Fill Seal Packaging Machine:

| Model | HX-420 | HX-520 | HX-720 |

| Max. bag width | 200mm | 250mm | 350mm |

| Bag length | 50-300mm | 80-350mm | 100-450mm |

| Film thickness | 0.04-0.08mm | 0.04-0.08mm | 0.05-0.1 mm |

| Packing speed | 30-60bag/min | 30-60bag/min | 10-30bag/min |

| Accuracy | <±1-2 | <±1-2 | <±2-3 |

| Power specification | 3.0kw/220V,50/60Hz | 3.5kw/220V,50/60Hz | 4.0kw/220V,50/60Hz |

| Air consumption | 0.6m2/min | 0.6m2/min | 0.7m2/min |

| Overall dimension | 3500x2000x3700mm | 3500x2000x3900mm | 3500x2000x4100mm |

| Gross weight | 700Kg | 750Kg | 800Kg |

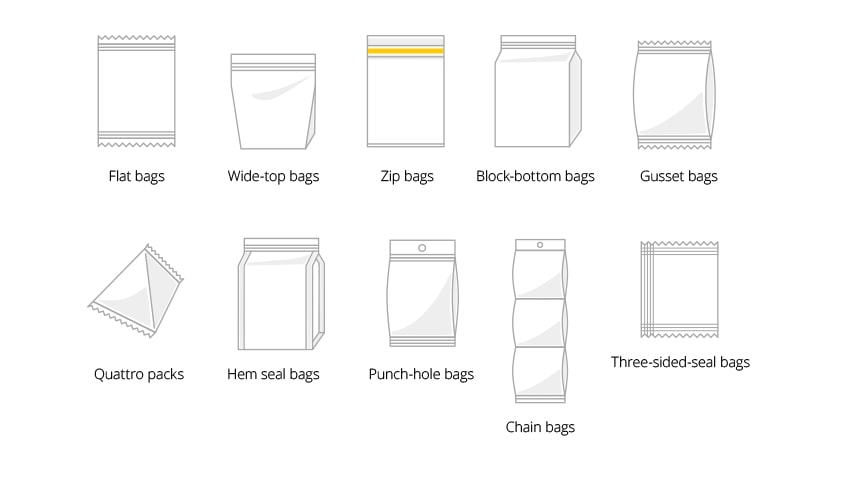

Bag Type of Automatic Multi-function Vertical Form Fill Seal Packaging Machine:

Video of Vertical Form Fill Seal Packaging Machine:

Packaging and shipping of Automatic Multi-function Vertical Form Fill Seal Packaging Machine:

We use the waterproof film multi-layer winding machine and then use wooden boxes for packaging, which can effectively prevent moisture and collision during transportation;

In transportation, we use sea transportation, of course, you can also choose other transportation methods.

After purchase, we will ship it to you as soon as possible. The exact arrival time will vary according to the distance. You can consult online customer service or leave us a message, and we will reply to you in time.

Submitted successfully

We will contact you as soon as possible